You are here

Crystal plasticity simulations reveal cooperative plasticity mechanisms leading to enhanced strength and toughness in gradient nanostructured metals

Dear Colleagues,

I invite you to read our recent paper published in Acta Materialia: 10.1016/j.actamat.2024.119835

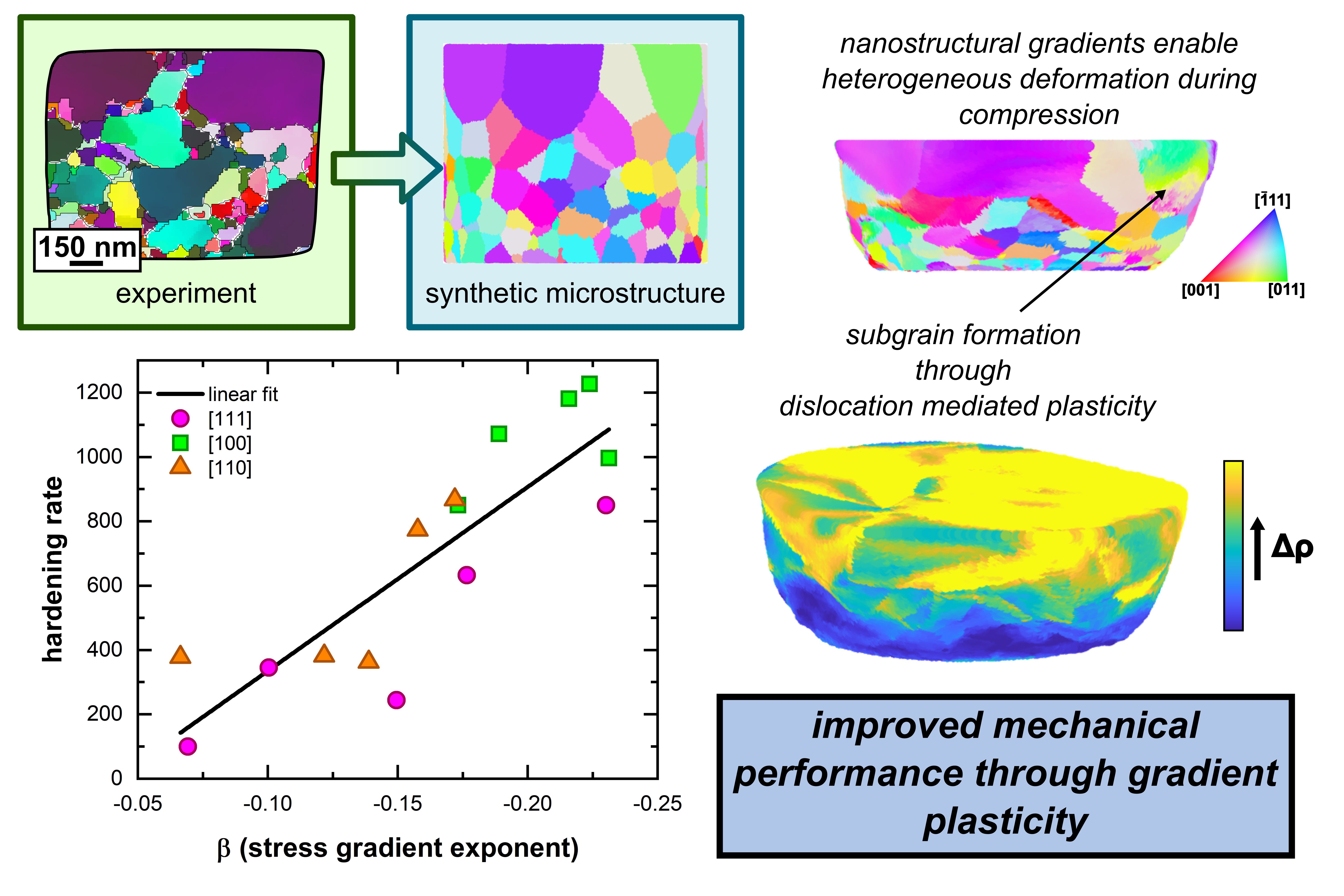

We use thermodynamically consistent crystal plasticity modeling to investigate the mechanical behavior and cooperative intra- and inter-granular plasticity mechanisms that emerge in gradient nano grained and nanostructured metals. We also developed a 3D synthetic microstructure generation algorithm that creates synthetic structures--which wasn't possible with commercial grain structure generation softwares--that reflects the experimentally observed gradient grain structures and gradient dislocation density. Modeling is performed in 3D and at the exact scale of experiments. Our study shows that using the dislocation density gradients measured from experiments instead of a phenomenological Hall-Petch relation results in better agreement with experimentally measured stress-strain response. It further reveals that stress exponent of the gradient stress that emerges in the gradient nano grained metals exhibits strong correlation to the hardening rate observed during deformation. It also underscores that not only the gradient grain structure matters, but also a specific constellation of grains in the system is essential to achieving synergistic strength and toughness in metals.

************

Abstract

Heterogeneous deformation is thought to provide the strengthening in gradient nanostructured metals, but the underlying plasticity mechanisms and optimal gradient structures for attaining improved mechanical performance remain elusive. Through crystal plasticity simulations of three-dimensional heterogeneous nanostructures, we reveal the heterogeneous-deformation-induced plasticity mechanisms which evoke increased flow strength and strain hardening. We have developed a synthetic microstructure generation algorithm which replicates both the microstructural features and external geometry of experimentally characterized samples—providing a direct comparison between the mechanical response recorded in simulations and experiments. Aligning well with experiments, the simulations show synergistically enhanced mechanical properties. High strain hardening rates directly correlate to large stress gradients that emerge due to heterogeneous deformation. Samples with smooth grain size gradients exhibit the most extreme stress gradients and correspondingly higher strain hardening rates. Large increases in dislocation density—especially within larger grains—and high intra- and inter-granular crystal rotation are plasticity mechanisms common to samples which exhibit high mechanical performance. Although the nanostructural gradients have pronounced influence over the mechanical performance, samples with the same grain size and dislocation density gradients exhibit varied mechanical properties. We show that the distribution of initial grain orientations and the microstructural constraints placed on larger grains also influence the active plasticity mechanisms providing improved mechanical properties.

- Ramathasan Thevamaran's blog

- Log in or register to post comments

- 1205 reads

Recent comments